Graphic Details

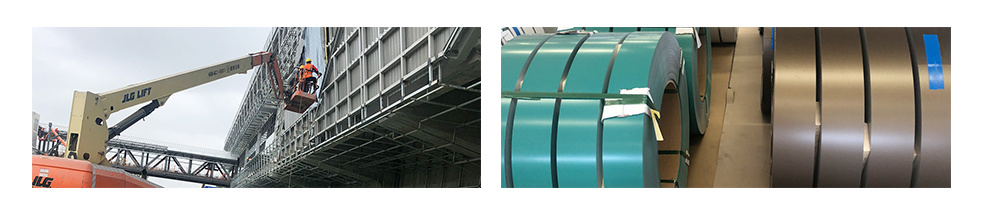

Printed Color Aluminum Coil

Color coated steel sheet is refined by chemical pretreatment, initial coating and fine coating processes. The quality of coating is far more uniform, stable and ideal than that of single piece spraying or brushing on formed metal surface.

Color coated steel plate to have excellent decorative, molding, corrosion resistance, strong adhesion of the coating, can be maintained for a long time color novelty. Since the color coated steel plate can achieve steel instead of wood, efficient construction, energy saving, pollution prevention and other good economic results, it has become the ideal material for today's selection of building panels.

Color coated steel plate usually refers to the substrate surface treatment after coating (roller coating) paint or adhesive organic film and baked products, can be further processed into the final product. It is called "pre-painted steel plate" and "plastic steel plate" abroad. The product has a beautiful color or pattern, so it is also called "color coated steel". In our country, color coated steel plate is more popular, and referred to as "color coated plate" or "color plate".

Uses of printed colored aluminum coils

Buildings: Exterior materials (roofing materials, wall materials) for industrial use, commercial use, residential use, and public facility use

Buildings: interior materials, interior wall materials, ceiling materials, partitions, fire doors

Building accessories: window panels, signboards

Home appliances: Oil/gas boilers, rice containers, portable gas stoves, etc.

Uses of stamped boards

The quality of the coating is important for construction in addition to the performance of the coating itself, and we are responsible for construction consultation for the coating sold.

★ Material: Pre-treated galvanized, steel, cold-rolled steel.

★ Diluent: Specialized diluent.

★ Painting viscosity: bottom, back: 40-50 "/ 25 ℃, face: 60-80 "/ 25 ℃ (according to customer requirements and site conditions)

★ Film thickness: front: ≥20μm; back: ≥5μm

★ Drying conditions (pmt): EPO/PCM/PU216-224Cx30"~40" (bottom go to the lower limit, face go to the upper limit)

★ Standing time:10~30"

Remarks:Color steel bottom paint does not test its performance separately, need primer cover paint surface test.